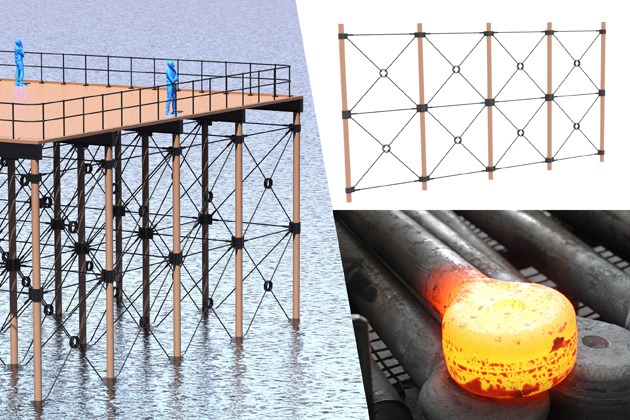

Bespoke Tension System Bracing Components For Southend Pier Restoration

Southend Pier, the world’s longest pleasure pier and a Grade II listed structure, is undergoing a major restoration to safeguard it for future generations. The multi-million-pound programme, funded by Southend City Council, demands specialist structural expertise and a robust UK supply chain capable of delivering high-quality engineered components.

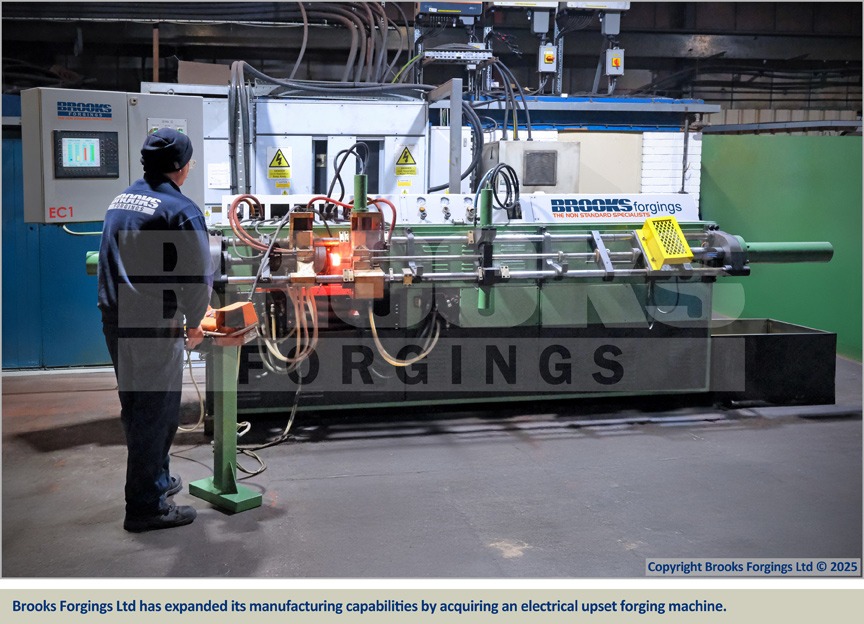

Brooks Forgings Ltd is working with several engineering firms to manufacture and supply bespoke bracing tension system parts for the pier’s main structural support frames (anchor bays). These assemblies provide essential rigidity while allowing for expansion and contraction in a harsh marine environment. Supplied components include forged one-piece eye rods, clevis ends, cross-bracing, tension rings, pile bracketry and associated fittings.

Bespoke forged tensioning eye rods were produced in M36 from S355 material, in lengths up to 2400 mm. Heavy-duty forged clevis ends were made from 70 mm diameter S355, with 140 mm OD eyes; fifty units were supplied with M36 internal threads. Each anchor bay employs multiple cross-brace tensioning sets with custom fixing bracketry mounted to the piles.

Given the pier’s age and heritage, parts must respect Victorian design and appearance while benefiting from modern materials and manufacturing. To maximise durability, all components are galvanised, T-washed and finished with two coats of Interzone® 954 epoxy, a coating formulated for offshore splash zones and immersed conditions.

Brooks Forgings welcomes enquiries from engineers involved in pier restoration and can support the specification, manufacture and supply of tensioning system components for similar projects.

Visit the Brooks Forgings Ltd website for more information on Bespoke Tension System Bracing Components For Southend Pier Restoration